In bioproduction, yields of products must be calculated precisely for accurate evaluation of various fermentation conditions. To evaluate productivity of microorganisms, product amounts per unit of medium volume (e.g., mg-product/L-broth), and/or product amounts per unit of a microorganism amount (e.g., mg-product/mg-dry cell weight) are often used. Nonetheless, detailed procedures for calculation of these production yields are often omitted in research articles, whereas methods for product quantification are described well. Here, we describe a detailed calculation procedure from our previous studies on glutathione production by Saccharomyces cerevisiae. This procedure can be applied to various other products and microorganisms, and therefore, may prove to be useful in various other bioproduction studies.

Keywords: Saccharomyces cerevisiae (酿酒酵母), Glutathione (谷胱甘肽), GSH (GSH), GSSG (GSSG), Aggregated microorganisms (聚集的微生物)

Background

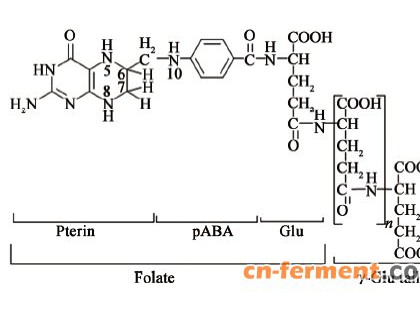

Glutathione is the most abundant thiol-containing tripeptide in all living organisms and functions as a bioactive substance with varied roles in cells, e.g., as redox and antidotal agents. Therefore, glutathione is widely used in the medical, food, and cosmetic industries nowadays, and the demand has increased in recent years. Glutathione is industrially produced mainly by fermentation using Saccharomyces cerevisiae, which originally contains a high concentration of glutathione and has served as a safe, food-producing microorganism. Studies of microbial glutathione production in various microorganisms will become more important in the future. To evaluate the productivity in terms of glutathione via fermentation by various microorganisms, here we describe our detailed procedures of sample preparation, quantification of reduced and oxidized glutathione by high performance chromatography (HPLC), and calculations of two types of yield (Hara et al., 2012; Hara et al., 2015; Kiriyama et al., 2013; Kobayashi et al., 2017).

Materials and Reagents

- 200 μl pipette tips (FCR&Bio, catalog number: AG-200-FP-Y )

- 1,000 μl pipette tips (FCR&Bio, catalog number: AG-1000B )

- 1.5 ml microcentrifuge tubes (FUKAEKASEI and WATSON, catalog number: 131-815C )

- 50 ml centrifuge tubes (Corning, catalog number: 430291 )

- Filter unit with 0.22 μm pore size (Shimadzu, catalog number: GLCTD-MCE1322 )

- Saccharomyces cerevisiae

- Yeast cell culture medium

- Ultrapure water (Milli-Q)

- Ice

- Ethylenediaminetetraacetic acid (EDTA) disodium salt dihydrate (NACALAI TESQUE, catalog number: 15111-45 )

- Sodium hydroxide (NaOH) (NACALAI TESQUE, catalog number: 31511-05 )

- Potassium dihydrogen phosphate (KH2PO4) (Wako Pure Chemical Industries, catalog number: 163-04265 )

- 1-Heptanesulfonate (NACALAI TESQUE, catalog number: 31528-92 )

- Phosphoric acid (Wako Pure Chemical Industries, catalog number: 162-20492 )

- Methanol (NACALAI TESQUE, catalog number: 21929-23 )

- Yeast extract dried (NACALAI TESQUE, catalog number: 15838-45 )

- Hipolypepton (NIHON PHARMACEUTICAL, catalog number: 392-02115 )

- D-(+)-Glucose (NACALAI TESQUE, catalog number: 16805-35 )

- Aureobasidin A (Takara Bio, catalog number: 630499 )

- 99.5% Ethanol (NACALAI TESQUE, catalog number: 14713-95 )

- Agar powder (NACALAI TESQUE, catalog number: 01028-85 )

- Standard Buffer Solution (pH 4.01) (NACALAI TESQUE, catalog number: 37219-75 )

- Standard Buffer Solution (pH 6.86) (NACALAI TESQUE, catalog number: 37220-35 )

- Standard Buffer Solution (pH 9.18) (NACALAI TESQUE, catalog number: 37221-25 )

- YPD medium (see Recipes)

- Aureobasidin A stock solution (see Recipes)

- 500 mM EDTA (see Recipes)

- 100 mM EDTA (see Recipes)

- HPLC mobile phase (see Recipes)

Equipment

- Micropipetter (volume range 20-200 μl) (Nichiryo, model: NPX-200 )

- Micropipetter (volume range 100-1,000 μl) (Nichiryo, model: NPX-1000 )

- Block heater (ASTEC, model: BI-516C )

- Aluminum microtube rack (Bio Medical Science, model: BMS-D081 )

- Centrifuge (KUBOTA, model: 3740 )

- Centrifuge rotor for 1.5 ml microcentrifuge tubes (maximum capacity is 21,880 x g) (KUBOTA, model: AF-2236 )

- Centrifuge rotor for 50 ml centrifuge tubes (maximum capacity is 22,140 x g) (KUBOTA, model: AF-5004CH )

- Glass test tube (NICHIDEN RIKA GLASS, model: 101015 )

- Baffled Erlenmeyer flask (AGC TECHNO GLASS, model: 4551FK200R )

- Silicone sponge tapered plug closure (Shin-Etsu Polymer, model: T-19 )

- Silicone sponge closure (Shin-Etsu Polymer, model: C-40 )

- Spectrophotometer (Shimadzu, model: UVmini-1240 )

- Spectrophotometer cell (Hellma, model: 104-10-40 )

- High-performance liquid chromatography system (Shimadzu, model: Pro minence)

- Octa decyl silyl (ODS) column (YMC, model: YMC-Pack ODS-A )

- Electronic scale (Mettler-Toledo International, model: XS105DU )

- Vortex mixer (Scientific Industries, model: Vortex-Genie 2 )

- Ice-making machine (HOSHIZAKI, model: CM-100K )

- Deep freezer (temperature range: from -20 to -30 °C) (Panasonic, model: MDF-U539 )

- Deep freezer (temperature range: from -50 to -85 °C) (PHC, model: MDF-U33V-PJ )

- pH meter (Horiba, model: F-52 )

- Forced air flow oven (Tokyo Rikakikai, model: WFO-1210 )

- Disposable loop (AS ONE, model: 6-488-02 )

- Incubator for solid preculture (Sanyo, model: MIR-153 )

- Incubator for liquid preculture (TAITEC, model: BR-43FL・MR )

- Incubator for glutathione production (TAITEC, model: G・BR-200 )

Procedure

- Glutathione production

- An S. cerevisiae strain was streaked with a disposable loop on the YPD solid medium and grown at 30 °C for 72 h.

- A single grown colony was inoculated into 5 ml of the YPD liquid medium in a 25 ml glass test tube closed with a tapered plug closure made of silicone sponge. The bacteria were aerobically grown with agitation at 200 rpm for 18 h at 30 °C.

- Transfer 50 μl of the grown yeast culture into a 1.5 ml microtube. Add 750 μl of ultrapure water and 200 μl of 500 mM EDTA to the 1.5 ml microtube and mix thoroughly by vortexing.

- Measure OD600 of this diluted yeast suspension in the EDTA solution.

- To determine OD600 of the original yeast preculture (ODPC), we multiplied the measured OD600 by 20 (dilution factor).

- The grown cells were inoculated into 20 ml of the YPD liquid medium in a 200 ml baffled Erlenmeyer flask plugged with a silicone sponge closure and were grown at 30 °C with agitation at 150 rpm for up to 48 h (Figure 1). The yeast cell culture volume (ml) for inoculation was calculated using the equation below. In the following equation, 20 and 0.03 indicate the total volume (μl) of the YPD liquid medium used for glutathione fermentation and the initial cell density (OD600), respectively.

- The yeast culture (1 ml) grown in a baffled Erlenmeyer flask was sampled at 24 and 48 h.

Figure 1. Schematic outline of glutathione production. A more detailed procedure is described in Procedure A.

- Determination of biomass concentration

- Cultivate yeast under the conditions described in Procedure A.

- Transfer 50 μl of the yeast culture (grown for glutathione production) into a 1.5 ml microtube. Add 200 μl of 500 mM EDTA and 750 μl of ultrapure water up to the 1.5 ml label in the microtube and mix thoroughly by vortexing.

- Measure OD600 of this diluted yeast suspension in an EDTA solution.

- To determine OD600 of the original yeast culture, multiply the measured OD600 by 20 (dilution factor).

- Centrifuge (16,000 x g, 10 min) all the yeast culture medium in 50 ml centrifuge tubes.

- Discard the supernatant and add 20 ml of room temperature ultrapure water to the cell pellet and thoroughly resuspend it by vortexing.

- Repeat this wash procedure one more time and re-pellet the cells.

- Add an adequate volume of 100 mM EDTA to the cell pellet to achieve optical density [at 600 nm (OD600) of the cell suspension] of approximately 1.0.

- Dilute the cell suspension with room temperature 100 mM EDTA to prepare 2-, 4-, 8-, and 16-fold diluted cell suspensions, and measure OD600 of these serial dilutions.

- Weigh empty open 50 ml centrifuge tubes and centrifuge (16,000 x g, 10 min) 20 ml of these cell suspensions in these tubes.

- Remove the supernatant and incubate the open centrifuge tube at 80 °C in a forced air flow oven overnight to dry the cells sufficiently.

- Weigh each 50 ml centrifuge tube with the dry cell pellet and calculate the weight of the dry cell pellet by subtracting the weight of the empty tube from the total weight (Figure 2).

Figure 2. Schematic outline of determination of biomass concentration. More detailed procedure is described in Procedure B.

- Construct a calibration curve for OD600 and biomass concentration ([g-dry cell weight]/[L-broth]). An example of a calibration curve is illustrated in Figure 3.

Figure 3. Example of calibration curve for OD600 and biomass concentration. Cells of S. cerevisiae GCI strain grown in YPD medium at 30 °C for 48 h were used for the construction of this calibration curve.

- Measurement of cell concentration and cell disruption

- Transfer 1 ml of the yeast culture grown for glutathione production in a 1.5 ml microtube. Add 250 μl of 500 mM EDTA to the 1.5 ml microtube and mix thoroughly by vortexing.

- Transfer 50 μl of this yeast culture containing 100 mM EDTA into a fresh 1.5 ml microtube. Add 950 μl of ultrapure water into the 1.5 ml microtube and mix thoroughly by vortexing.

- Measure OD600 of this diluted yeast suspension in the EDTA solution.

- To determine OD600 of the original yeast culture (ODC), multiply the measured OD600 by 25 (dilution factor).

- Centrifuge (16,000 x g, 1 min) 1.2 ml of the residual yeast culture in a 100 mM EDTA solution and resuspend the pellet in 1 ml of ultrapure water by vortexing.

- Repeat this wash procedure one more time and re-pellet the cells.

- Add an adequate volume (μl) of ultrapure water calculated by means of the equation below for the cell pellet and resuspend it well. In the following equation, 960 and 35 mean residual yeast culture volume (μl) without the EDTA solution, and OD600 that is optimal for glutathione determination, respectively.

- Transfer 980 μl of distilled water and 20 μl of the concentrated yeast cell suspension to a different 1.5 ml microtube and mix thoroughly.

- Measure OD600 of this diluted yeast cell suspension and multiply the measured OD600 by 50 (dilution factor) to obtain OD600 of the concentrated resuspended cells (ODR).

- To disrupt yeast cells, incubate the concentrated cell suspension at 95 °C for 3 min and then cool on ice for 3 min.

- Centrifuge (16,000 x g, 10 min) the disrupted cell suspension, and transfer 50 μl of the supernatant (solution containing cell content) to a new 1.5 ml microtube. The cell content solution can be stored at -20 °C before HPLC analysis (Figure 4). At least three samples per strain are needed for accurate measurements.

Figure 4. Schematic outline of measurement of cell concentration and cell disruption. A more detailed procedure is described in Procedure C.

- HPLC analysis

- Add 200 μl of the HPLC mobile phase to 50 μl of the cell content solution.

- Filter the 5-fold diluted cell content solution through the filter unit with 0.22 μm pore size to obtain an HPLC sample.

- Set each parameter as follows.

Pump: run time, 25 min; flow rate, 1 ml/min; maximum pressure, 20.0 MPa.

UV detector: deuterium arc lamp was used, response, 1.0 sec; internal temperature, 40 °C; wavelength, 210 nm.

Column oven: temperature, 30 °C; maximum temperature, 40 °C.

Auto sampler: injection volume, 20 μl; syringe speed, 15 μl/sec; flush volume, 200 μl; needle stroke, 52 mm; flush speed 35 μl/sec; temperature 10 °C. - Equilibrate the column to allow the mobile phase to flow for at least 90 min at a flow rate of 1 ml/min.

- Start analysis according to the HPLC manual to quantify reduced and oxidized glutathione in the HPLC sample. Examples of HPLC analysis are shown in Figure 5.

Figure 5. Examples of HPLC analysis. A. HPLC analysis of a sample containing 20 mg/L GSH and GSSG. B. HPLC analysis of a sample extracted from the S. cerevisiae GCI strain cells grown in the YPD medium at 30 °C for 48 h.

Data analysis

- Calculate cell concentration ([g-dry cell weight]/[L-broth]) from ODC and from the calibration curve of OD600 and biomass ([g-dry cell weight]/[L-broth]).

- Calculate the cell concentration rate by means of the following equation:

- Calculate volumetric glutathione production (VGP, mg/[L-broth]) via the following equation. In this equation, 5 means a dilution factor for the HPLC sample.

- Calculate glutathione content (GC) (mg/[mg-cells]) using the following equation:

Notes

- If the resolution of an ODS column decreased, and HPLC peaks of GSH and GSSG became difficult to separate. An increase in methanol concentration in the HPLC mobile phase may improve the separation of the peaks.

- In this protocol, the addition of EDTA to yeast culture is needed to measure OD600 accurately. EDTA inhibits lectin activity on the cell surface and consequently prevents cell aggregation. If EDTA was not added, OD600 of yeast decreased via aggregation as compared with the original figure.

- When 250 μl of 500 mM EDTA was added to 1,000 μl of the yeast culture medium, and 50 μl of this mixture (total volume was 1,250 μl) was used to measure OD600; 1,200 μl of this residual mixture consisted of 960 μl of the yeast culture medium and 240 μl of 500 mM EDTA. The value of 960 in the equation in Step C7 is this residual volume of the original yeast culture medium.

- In many cases, GSH and GSSG concentrations in an HPLC sample were within the calibration curve, when OD600 of the cell suspension before disruption was ~35. Therefore, this protocol contained this value of 35 in the calculation of the adequate volume of ultrapure water.

Recipes

- YPD medium (1 L)

10 g of Yeast extract dried

20 g of hipolypeptone

20 g of D-(+)-glucose

1.0 ml of aureobasidin A stock solution (if needed)

20 g of agar powder (if needed)

Ultrapure water - Aureobasidin A stock solution (1 L)

0.5 mg of aureobasidin A

99.5% ethanol - 500 mM EDTA (1 L)

186.12 g of EDTA disodium salt dihydrate

Ultrapure water

Adjust pH to 8.0 with 1.0 M NaOH - 100 mM EDTA (1 L)

200 ml of 500 mM EDTA

Ultrapure water - HPLC mobile phase (1 L)

6.12 g of KH2PO4

1.818 g of 1-heptanesulfonate

212.6 ml of methanol

Ultrapure water

Adjust pH to 2.8 with 98% phosphoric acid

Acknowledgments

This work was supported by a Special Coordination Fund for Promoting Science and Technology, Creation of Innovative Centers for Advanced Interdisciplinary Research Areas (Innovative Bioproduction, Kobe) from the Ministry of Education, Culture, Sports, and Science and Technology (MEXT), Japan. This protocol was adapted from our previous works (Hara et al., 2012; Hara et al., 2015; Kiriyama et al., 2013; Kobayashi et al., 2017). The authors have no conflict of interest or competing interest.

References

- Hara, K. Y., Aoki, N., Kobayashi, J., Kiriyama, K., Nishida, K., Araki, M. and Kondo, A. (2015). Improvement of oxidized glutathione fermentation by thiol redox metabolism engineering in Saccharomyces cerevisiae. Appl Microbiol Biotechnol 99(22): 9771-9778.

- Hara, K. Y., Kiriyama, K., Inagaki, A., Nakayama, H. and Kondo, A. (2012). Improvement of glutathione production by metabolic engineering the sulfate assimilation pathway of Saccharomyces cerevisiae. Appl Microbiol Biotechnol 94(5): 1313-1319.

- Kiriyama, K., Hara, K. Y. and Kondo, A. (2013). Oxidized glutathione fermentation using Saccharomyces cerevisiae engineered for glutathione metabolism.Appl Microbiol Biotechnol 97(16): 7399-7404.

- Kobayashi, J., Sasaki, D., Hara, K. Y., Hasunuma, T. and Kondo, A. (2017). Enzymatic improvement of mitochondrial thiol oxidase Erv1 for oxidized glutathione fermentation by Saccharomyces cerevisiae. Microb Cell Fact 16(1): 44.

简介

在生物生产中,必须精确计算产品的产量,以准确评估各种发酵条件。 为了评估微生物的生产力,每单位培养基体积的产物量(例如,mg-产物/ L-肉汤)和/或每单位微生物量的产物量(例如, ,毫克产品/毫克干细胞重量)经常使用。 尽管如此,在研究文章中常常忽略用于计算这些产量的详细程序,而产品量化的方法则被很好地描述。 在这里,我们描述了我们以前关于酿酒酵母产生谷胱甘肽的研究的详细计算过程。 该程序可以应用于各种其他产品和微生物,因此可能证明可用于各种其他生物生产研究。

【背景】谷胱甘肽是所有生物体中含量最高的含巯基三肽,并且作为在细胞中具有不同作用的生物活性物质起作用,例如作为氧化还原和解毒剂。因此,谷胱甘肽如今被广泛用于医疗,食品和化妆品行业,并且近年来需求增加。谷胱甘肽在工业上主要通过使用原始含有高浓度谷胱甘肽的酿酒酵母进行发酵生产,并且已经作为安全的食品生产微生物。对各种微生物中的微生物谷胱甘肽产生的研究在未来将变得更加重要。为了评估各种微生物发酵产生谷胱甘肽的效率,我们在这里描述了我们详细的样品制备程序,高效色谱(HPLC)定量还原和氧化谷胱甘肽的方法,以及两种产量的计算方法(Hara ) 2012; Hara等人,2015; Kiriyama等人,2013; Kobayashi等人 2017年)。

关键字:酿酒酵母, 谷胱甘肽, GSH, GSSG, 聚集的微生物

材料和试剂

- 200μl移液管吸头(FCR& Bio,目录号:AG-200-FP-Y)

- 1000μl移液管吸头(FCR& Bio,目录号:AG-1000B)

- 1.5 ml微量离心管(FUKAEKASEI和WATSON,目录号:131-815C)

50 ml离心管(Corning,目录号:430291)- 具有0.22μm孔径的过滤器单元(Shimadzu,目录号:GLCTD-MCE1322)

- 酿酒酵母(Saccharomyces cerevisiae)

- 酵母细胞培养基

- 超纯水(Milli-Q)

- 冰

- 乙二胺四乙酸(EDTA)二钠盐二水合物(NACALAI TESQUE,目录号:15111-45)

- 氢氧化钠(NaOH)(NACALAI TESQUE,目录号:31511-05)

- 磷酸二氢钾(KH 2 PO 4)(Wako Pure Chemical Industries,目录号:163-04265)

- 1-庚烷磺酸盐(NACALAI TESQUE,目录号:31528-92)

- 磷酸(Wako Pure Chemical Industries,目录号:162-20492)

- 甲醇(NACALAI TESQUE,目录号:21929-23)

- 干燥酵母提取物(NACALAI TESQUE,目录号:15838-45)

- Hipolypepton(NIHON PHARMACEUTICAL,目录号:392-02115)

- D - (+) - 葡萄糖(NACALAI TESQUE,目录号:16805-35)

- Aureobasidin A(Takara Bio,目录号:630499)

- 99.5%乙醇(NACALAI TESQUE,目录号:14713-95)

- 琼脂粉(NACALAI TESQUE,目录号:01028-85)

- 标准缓冲溶液(pH 4.01)(NACALAI TESQUE,目录号:37219-75)

- 标准缓冲液(pH 6.86)(NACALAI TESQUE,目录号:37220-35)

- 标准缓冲溶液(pH 9.18)(NACALAI TESQUE,目录号:37221-25)

- YPD中(见食谱)

- Aureobasidin A储备液(见食谱)

- 500 mM EDTA(见食谱)

- 100 mM EDTA(见食谱)

- HPLC流动相(见食谱)

设备

- Micropipetter(容量范围20-200μl)(Nichiryo,型号:NPX-200)

- Micropipetter(体积范围100-1,000μl)(Nichiryo,型号:NPX-1000)

- 座式加热器(ASTEC,型号:BI-516C)

铝微管架(生物医学科学,型号:BMS-D081)- 离心机(KUBOTA,型号:3740)

- 用于1.5ml微量离心管的离心机转子(最大容量为21,880×g)(KUBOTA,型号:AF-2236)

- 用于50ml离心管的离心机转子(最大容量为22,140×g)(KUBOTA,型号:AF-5004CH)

- 玻璃试管(NICHIDEN RIKA GLASS,型号:101015)

带挡板锥形瓶(AGC TECHNO GLASS,型号:4551FK200R)- 硅胶海绵锥形塞封(信越聚合物,型号:T-19)

- 硅胶海绵封口(信越聚合物,型号:C-40)

- 分光光度计(岛津,型号:UVmini-1240)

- 分光光度计池(Hellma,型号:104-10-40)

- 高效液相色谱系统(岛津,型号:Pro minence)

- Octa癸基甲硅烷基(ODS)柱(YMC,型号:YMC-Pack ODS-A)

- 电子秤(梅特勒 - 托利多国际,型号:XS105DU)

- 涡旋混合器(Scientific Industries,型号:Vortex-Genie 2)

- 制冰机(HOSHIZAKI,型号:CM-100K)

- 深冷冻机(温度范围:-20至-30°C)(Panasonic,型号:MDF-U539)

- 深冷冻机(温度范围:-50至-85°C)(PHC,型号:MDF-U33V-PJ)

- pH计(Horiba,型号:F-52)

- 强制空气流动烤箱(东京Rikakikai,型号:WFO-1210)

- 一次性回路(AS ONE,型号:6-488-02)

固体预培养培养箱(Sanyo,型号:MIR-153)- 液体预培养培养箱(TAITEC,型号:BR-43FL·MR)

- 谷胱甘肽生产培养箱(TAITEC,型号:G·BR-200)

程序

- 谷胱甘肽生产

- 一个S。将酿酒酵母菌株用YPD固体培养基上的一次性环划线,并在30℃生长72小时。

- 将单个生长的菌落接种到25ml玻璃试管中的5ml YPD液体培养基中,该玻璃试管用硅酮海绵制成的锥形塞封闭。

细菌在30℃以200rpm搅拌18小时后有氧生长。 - 将50μl生长的酵母培养物转移到1.5ml微管中。

加入750μl超纯水和200μl500 mM EDTA到1.5 ml微量管中并通过涡旋混匀。 - 在EDTA溶液中测量该稀释的酵母悬浮液的OD 600。

- 为了确定原始酵母前培养物(ODPC)的OD 600,我们将测量的OD 600乘以20(稀释因子)。

- 将生长的细胞接种到20ml YPD液体培养基中,该培养基在用硅酮海绵封口塞住的200ml带挡板的锥形瓶中并在30℃下以150rpm搅拌长达48小时(图1)。使用下面的公式计算接种的酵母细胞培养体积(ml)。在下面的等式中,20和0.03分别表示用于谷胱甘肽发酵的YPD液体培养基的总体积(μl)和初始细胞密度(OD 600)。

培养24小时和48小时后,在带挡板的锥形瓶中培养酵母培养物(1毫升)

图1.谷胱甘肽生产的示意图更详细的程序在程序A中描述。

- 生物质浓度的测定

- 在程序A中描述的条件下培养酵母。

- 转移50微升的酵母培养物(生长谷胱甘肽生产)到1.5毫升微管。

添加200μl500 mM EDTA和750μl超纯水至微管中的1.5 ml标签,并通过涡旋混匀。 - 在EDTA溶液中测量该稀释的酵母悬浮液的OD 600。

- 为了确定原始酵母培养物的OD 600,将测量的OD 600乘以20(稀释因子)。

在50ml离心管中离心(16,000xg克,10分钟)所有酵母培养基。- 丢弃上清液,并添加20毫升室温超纯水的细胞沉淀,并彻底悬浮通过涡流。

- 重复洗涤程序一次,并重新沉淀细胞。

- 将足够体积的100mM EDTA加入细胞沉淀中以达到光密度[在细胞悬浮液的600nm(OD 600)下]约为1.0。

- 用室温100mM EDTA稀释细胞悬液以制备2-,4-,8-和16倍稀释的细胞悬浮液,并测量这些系列稀释液的OD 600。

- 称取空的开放的50ml离心管,并在这些管中离心(16,000×g,10分钟)20ml这些细胞悬浮液。

- 取出上清液,在80℃的强制空气流通烤箱中培养过夜的离心管,以充分干燥细胞。

- 用干细胞沉淀物称重每个50ml离心管,并通过从总重量中减去空管的重量来计算干细胞沉淀物的重量(图2)。

图2.生物质浓度测定示意图更详细的程序在程序B中描述。

- 构建OD 600和生物质浓度([干细胞重量] / [L-肉汤])的校准曲线。图3显示了校准曲线的一个例子。

图3. OD浓度和生物量浓度的校准曲线示例。 S 在30℃YPD培养基中生长48小时的酿酒酵母 GCI菌株用于构建此校准曲线。

- 细胞浓度和细胞破坏的测量

- 转移1毫升生长谷胱甘肽生产酵母培养在1.5毫升微管。

加入250μl500 mM EDTA到1.5 ml微量管中并通过涡旋混匀。 - 将50μl含有100mM EDTA的酵母培养物转移到新鲜的1.5ml微管中。

加入950微升超纯水到1.5毫升的微管中,并通过涡旋混匀。 - 在EDTA溶液中测量该稀释的酵母悬浮液的OD 600。

- 为了确定原始酵母培养物(ODC)的OD 600,将测量的OD 600乘以25(稀释因子)。

- 离心(16,000×g克,1分钟)1.2ml在100mM EDTA溶液中的残余酵母培养物,并通过涡旋将沉淀重悬于1ml超纯水中。

- 重复洗涤程序一次,并重新沉淀细胞。

- 根据以下公式计算出的细胞沉淀量,并加入适量的超纯水,并重新悬浮。在下面的等式中,960和35分别表示不含EDTA溶液的残余酵母培养物体积(μl)和分别对于谷胱甘肽测定最佳的OD 600分布。

- 将980μl蒸馏水和20μl浓缩酵母细胞悬浮液转移到不同的1.5 ml微型管中并充分混合。

- 测量该稀释的酵母细胞悬浮液的OD 600并将测量的OD 600乘以50(稀释因子)以获得OD 600浓缩的再悬浮细胞(ODR)。

- 为了破坏酵母细胞,将浓缩的细胞悬浮液在95℃孵育3分钟,然后在冰上冷却3分钟。

- 离心(16,000×g,10分钟)破碎的细胞悬液,并将50μl上清液(含有细胞内容物的溶液)转移到新的1.5ml微管中。在HPLC分析之前,细胞内容物溶液可以储存在-20℃(图4)。

每个菌株至少需要三个样品进行精确测量

图4.测量细胞浓度和细胞破坏的示意图更详细的程序在程序C中描述。

- 转移1毫升生长谷胱甘肽生产酵母培养在1.5毫升微管。

- HPLC分析

加入200μlHPLC流动相到50μl细胞内容物溶液中。

过滤5倍稀释的细胞内容物溶液,通过孔径为0.22μm的过滤器,获得HPLC样品。

如下设置每个参数 泵:运行时间25分钟;流速,1ml / min;最大压力,20.0 MPa。

紫外检测器:使用氘弧灯,响应时间1.0秒;内部温度,40°C;波长,210纳米。

柱温箱:温度30℃;最高温度,40°C。

自动采样器:进样量20μl;注射器速度,15μl/秒;冲洗量,200μl;针行程,52毫米;冲洗速度35μl/ sec;温度10°C。- 平衡色谱柱,使流动相以1 ml / min的流速流动至少90 min。

- 根据HPLC手册开始分析以量化HPLC样品中还原和氧化的谷胱甘肽。图5显示了HPLC分析的例子。

图5.HPLC分析的实例A.含有20mg / L GSH和GSSG的样品的HPLC分析。 B.从S中提取的样品的HPLC分析。酿酒酵母 GCI菌株细胞在YPD培养基中在30℃生长48小时。

数据分析

- 从ODC和OD 600和生物量的校准曲线计算细胞浓度([干细胞重量] / [L-肉汤])[[干细胞重量] / [L-肉汤] ])。

- 通过以下公式计算细胞浓度比率:

- 通过以下等式计算体积谷胱甘肽产量(VGP,mg / [L-肉汤])。在此等式中,5表示HPLC样品的稀释因子。

- 使用以下公式计算谷胱甘肽含量(GC)(mg / [mg-细胞]):

笔记

- 如果ODS色谱柱的分离度下降,GSH和GSSG的HPLC峰变得难以分离。

在HPLC流动相中甲醇浓度的增加可以改善峰的分离。 - 在此协议中,需要在酵母培养基中添加EDTA以精确测量OD 600。 EDTA抑制细胞表面上的凝集素活性并因此阻止细胞聚集。如果不添加EDTA,与原始数据相比,OD 600的酵母通过聚集减少。

- 当向1000μl酵母培养基添加250μl500mM EDTA时,使用50μl该混合物(总体积为1250μl)测量OD 600; 1200μl这种残留混合物由960μl酵母培养基和240μl500mM EDTA组成。

在步骤C7的公式中,960的值是原始酵母培养基的剩余体积。 - 在许多情况下,当样品破坏前的OD 600大约为35时,HPLC样品中的GSH和GSSG浓度在校准曲线内。因此,该协议在计算超纯水的充足体积时包含了35的这个值。

食谱

- YPD培养基(1升)

10克干酵母提取物

20克的hipolypeptone

20克D - (+) - 葡萄糖

1.0毫升aureobasidin A储备液(如果需要) 20克琼脂粉(如果需要)

超纯水 - Aureobasidin A储备液(1 L)

0.5毫克aureobasidin A

99.5%乙醇 - 500 mM EDTA(1 L)

186.12克EDTA二钠盐二水合物 超纯水

用1.0 M NaOH调节pH至8.0 - 100 mM EDTA(1 L)

200毫升500mM EDTA

超纯水 - HPLC流动相(1 L)

6.12g的KH 2 PO 4 4 1.818克的1-庚烷磺酸盐

212.6毫升甲醇

超纯水

用98%磷酸调节pH值至2.8

致谢

这项工作得到了日本教育,文化,体育和科学技术部(MEXT)的促进科学和技术特别协调基金,创建先进跨学科研究领域创新中心(创新生物生产,神户)的支持。该协议是根据我们以前的作品(Hara等人,2012年,Hara等人,2015年,Kiriyama等人,2013年)改编的; Kobayashi 等,2017)。作者没有利益冲突或利益冲突。

参考

- Hara,K. Y.,Aoki,N.,Kobayashi,J.,Kiriyama,K.,Nishida,K.,Araki,M.和Kondo,A。(2015)。 在酿酒酵母中通过巯基氧化还原代谢工程改进氧化型谷胱甘肽发酵。 Appl Microbiol Biotechnol 99(22):9771-9778。

- Hara,K.Y.,Kiriyama,K.,Inagaki,A.,Nakayama,H。和Kondo,A。(2012)。 通过酿酒酵母硫酸盐同化途径的代谢工程改善谷胱甘肽的产生 。 Appl Microbiol Biotechnol 94(5):1313-1319。

- Kiriyama,K.,Hara,K.Y.和Kondo,A。(2013)。氧化型谷胱甘肽发酵使用工程化谷胱甘肽代谢的酿酒酵母 。 Appl Microbiol Biotechnol 97(16):7399-7404。

- Kobayashi,J.,Sasaki,D.,Hara,K.Y.,Hasunuma,T.and Kondo,A。(2017)。 酿酒酵母氧化谷胱甘肽发酵线粒体巯基氧化酶Erv1的酶学改良 。 Microb Cell Fact 16(1):44.